Sewer Lift Station

Mission keeps you connected to your Lift Stations

Lift stations need monitoring

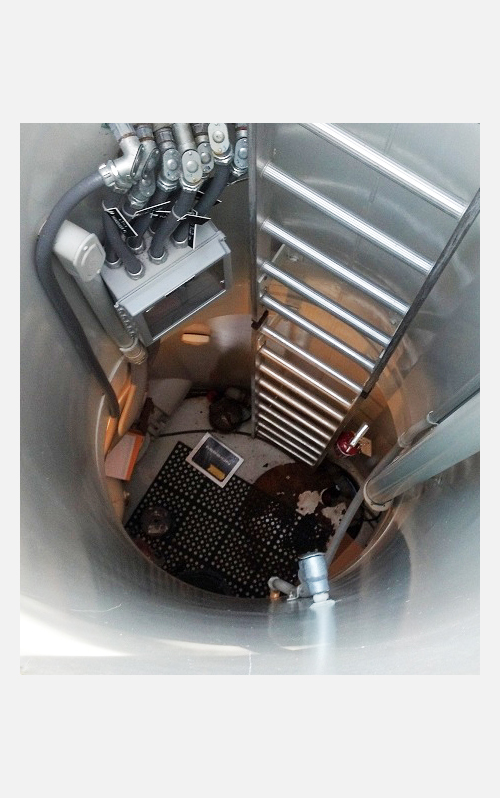

A lift station’s purpose is to pump wastewater from lower to higher elevations, ensuring sewage reaches treatment plants efficiently. Properly equipped stations run automatically and efficiently, ensuring wastewater is removed from communities. But leaving them unmonitored leaves utilities in constant state of reacting to emergency spills and learning too late when equipment fails, endangering station components and the delivery system as a whole.

A lift station includes key components like a wet well for collecting wastewater, pumps, and pump controllers that manage cycles based on water levels. Valves and piping direct the ow and prevent back ow, while ventilation systems control odors and hazardous gases. The force main is crucial for transporting wastewater under pressure to higher elevations. A simple monitoring solution alerts operators to high water levels or pump issues. Remote monitoring tracks the performance of these components, ensuring everything runs smoothly and efficiently.

What needs to be monitored?

- High water level

- Low water level

- A/C power loss

- Pump overload

- Pump failure

Cloud-Based SCADA

A cloud–based remote monitoring SCADA solution is crucial for preventing failures and flooding by providing early warnings of pump malfunctions, reducing health risks, and ensuring regulatory compliance. It enables proactive maintenance by detecting issues early, reducing downtime, and extending equipment lifespans. Real-time data enhances operational efficiency, lowers energy costs, and prevents emergency repairs. Accurate data ensures regulatory compliance and simplifies reporting. Continuous monitoring improves

system reliability by detecting anomalies promptly and using historical data for better planning.

Real-Time Updates

Real-time updates provide constant visibility into your lift station’s performance, ensuring you stay informed about critical system changes. With updates every two minutes or triggered by a 5% level change, you gain accurate, up-to-the-minute data for better decision-making. This rapid feedback allows operators to respond quickly to potential issues, minimizing downtime and disruptions. Real-time monitoring not only enhances operational control but also provides peace of mind, knowing your system is always under watch.

Daily/Hourly Graphs

Daily and hourly graphs present a clear visualization of pump starts, runtimes, and other critical data points. These graphs help operators identify anomalies, such as excessive starts or prolonged runtimes, which may indicate underlying issues. By analyzing trends over time, you can compare pump performance and diagnose inefficiencies with ease. This data-driven approach simplifies system management, making it easier to optimize performance and address concerns before they escalate.

Pump Insights

Detailed pump insights empower operators to track essential metrics like pump state changes, runtimes, and performance trends. These insights reveal critical information about pump health, enabling early detection of clogs, inefficiencies, or degradation. By analyzing pump activity, you can optimize energy use, schedule maintenance proactively, and extend equipment lifespan. Having this level of understanding ensures your lift station operates reliably and efficiently, reducing overall costs.

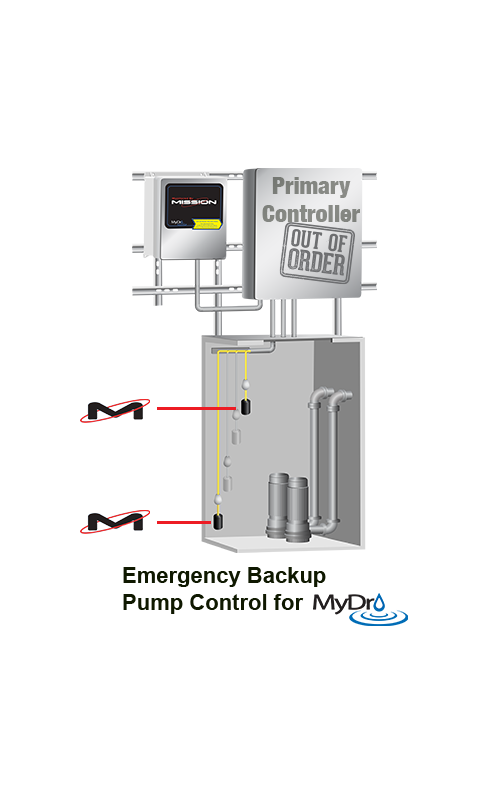

Emergency Backup Pump Control

A pump controller in a lift station automatically manages pump operations based on water levels, ensuring efficient and reliable wastewater management. It turns pumps on and off as needed, prevents overflows, and monitors system parameters like pump run times and potential alarm triggers.

Occasionally, pump controllers may fail due to issues such as electrical faults or software glitches. In these cases, replacing the controller can take several weeks, during which the lift station must be operated manually—a resource-intensive and less reliable process.

To address this challenge, Mission has introduced an optional Emergency Backup Pump Control feature in the MyDro 150 and 850 devices. This local, software-enabled feature allows the MyDro units to temporarily take over pump control for up to two pumps in the system, ensuring the lift station remains operational while waiting for a replacement pump controller. This innovative solution minimizes downtime, reduces manual intervention, and maintains system reliability during critical periods.